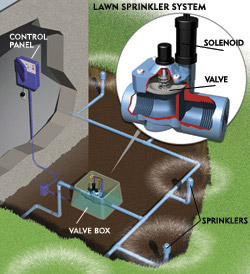

Underground sprinklers function through means of basic electronic and hydrolic technology. A 110 volt supplied controller, or sprinkler box sends a pre-determined 24 volt signal to an awaiting solenoid valve in the yard. This valve and all of the sprinklers that will be activated by this valve are known as a zone. Upon activation, the solenoid, which sits on top of the valve is magnetized lifting a small stainless steel plunger in its center. By doing this, the activated (or raised) plunger allows air to escape from the top of a rubber diaphragm located in the center of the valve. Water that has been charged and waiting on the bottom of this same diaphragm now has the higher pressure and lifts the diaphragm. This pressurized water is then allowed to escape down stream of the valve through a series of pipes, usually made of PVC. At the end of these pipes and flush to ground level (typically) are pre measured and spaced out sprinklers. These sprinklers can be fixed spray heads that have a set pattern and generally spray between 7 and 15 feet, full rotating sprinklers that can spray a broken stream of water from 20 to 40 feet, or small drip emitters that release a slow, steady drip of water on more delicate plants such as flowers and shrubs.

Most irrigation sprinklers are used as part of a sprinkler system, consisting of various plumbing parts, piping and control equipment. Piping is connected to the water source via plumbing fittings and the control system opens and closes valves to provide water on a schedule. The control provided varies depending on the equipment used; some systems are fully automated and even compensate for rain, runoff and evaporation, while others require much more user attention for the same effectiveness.